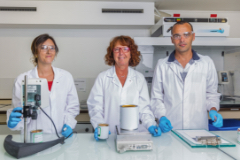

Almost 80 R&D engineers and technicians work in the 5 Group’s laboratories. And, thanks to them, nearly 20% of Cromology’s sales consist of products that have been developed within the last three years.

In addition to develop new products, R&D Teams carry out other tasks:

– guaranteeing the consistent paints production quality. A paint will be subjected to a total of twenty different tests. Teams will verify its viscosity, its opacity, its whiteness for a white paint, thickness as well as the film’s cleanness.

– handling complaints or nonconformities issued by clients.

– testing and approuving raw materials as alternatives or raw materials bringing a new funtionality to the paint.

– certifying the quality of color offer’s tints.